The Role of Hydraulic Hoses in Heavy-Duty Applications

Without the hose of your hydraulic system, your entire application would be completely non-functional. Pressurized oil would spurt everywhere, damaging the machinery and bringing operations to a standstill. The necessary components of hoses serve to maintain equipment functionality, avoid costly downtime, and enhance workplace safety. Explore the importance of hydraulic hoses by learning their role in heavy-duty applications.

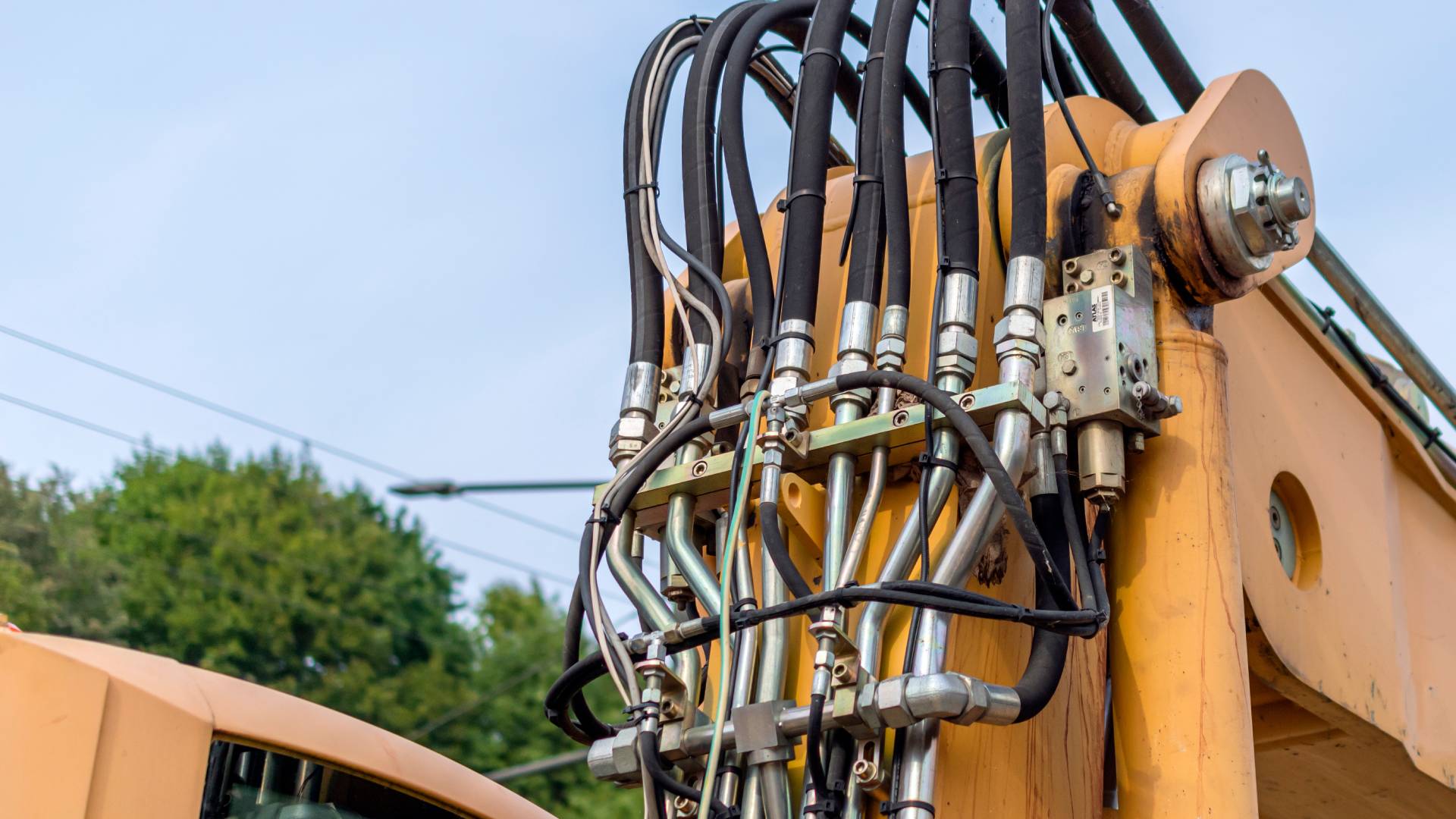

Fluid Transmission

At their core, hydraulic hoses are designed to transfer hydraulic fluid between components like pumps, valves, and actuators. This fluid transmission enables machinery to perform tasks such as lifting, compressing, or excavating.

Without a well-functioning hydraulic hose, fluid flow becomes restricted, directly affecting the efficiency and performance of your equipment. Consistently check for any blockages or unusual wear and tear to ensure seamless fluid movement.

Flexibility and Versatility

Unlike rigid pipes, hydraulic hoses provide the flexibility and adaptability required for various machine designs. A technician can bend, route, and shape the hose into tight spaces, making them incredibly versatile across different applications.

This flexibility minimizes vibration and stress on connected components while allowing the machinery to operate under dynamic conditions. It’s critical to select high-quality hoses that strike the right balance between flexibility and robustness for diverse operational demands.

Resistance to High Pressure

Heavy-duty machinery often operates under intense pressure. Hydraulic hoses are specifically engineered to withstand these high-pressure environments and deliver reliable performance.

However, as time progresses, you should begin looking for signs that you need to replace your hydraulic hose to ensure optimal performance from your machinery. Regular inspections can help you detect these issues early and ensure that hoses can handle the demands placed on them.

Durability in Extreme Conditions

Hydraulic hoses are built to perform even under the most extreme conditions, from freezing cold to scorching heat. Constructed using durable materials, including synthetic rubber and reinforced fibers, they are resistant to abrasion, chemicals, and environmental exposure.

This durability extends the lifespan of the system but also saves you on long-term replacement costs. Ensure you’re using the right type of hose for your machinery’s operating conditions to maximize reliability.

Safety and Leak Prevention

Hydraulic systems involve high-pressure fluid, which, if mishandled, can lead to dangerous leaks or bursts. Fortunately, high-quality hydraulic hoses are engineered to prevent such scenarios through advanced construction and secure fittings. Installing well-fitted and regularly inspected hoses significantly enhances workplace safety by mitigating leak-related injuries or equipment failures.

Understanding and appreciating the role of hydraulic hoses in heavy-duty applications better equips you to effectively manage and maintain your operations. When it’s time to evaluate or upgrade your machinery, inspect your hoses and replace them as needed to guarantee peak performance.