The Benefits of Investing in an Automatic Crimping Machine

Industrial manufacturing is all about optimization—streamlining processes, increasing output, and maintaining exceptional quality. Tools and machinery play a pivotal role in achieving these goals, and one such machine stands out for manufacturers seeking efficiency and precision—the automatic crimping machine. If you’re thinking of investing in an automatic crimping machine, our guide will explain the benefits of adding one to your process and how to care for it long-term.

What is an Automatic Crimping Machine?

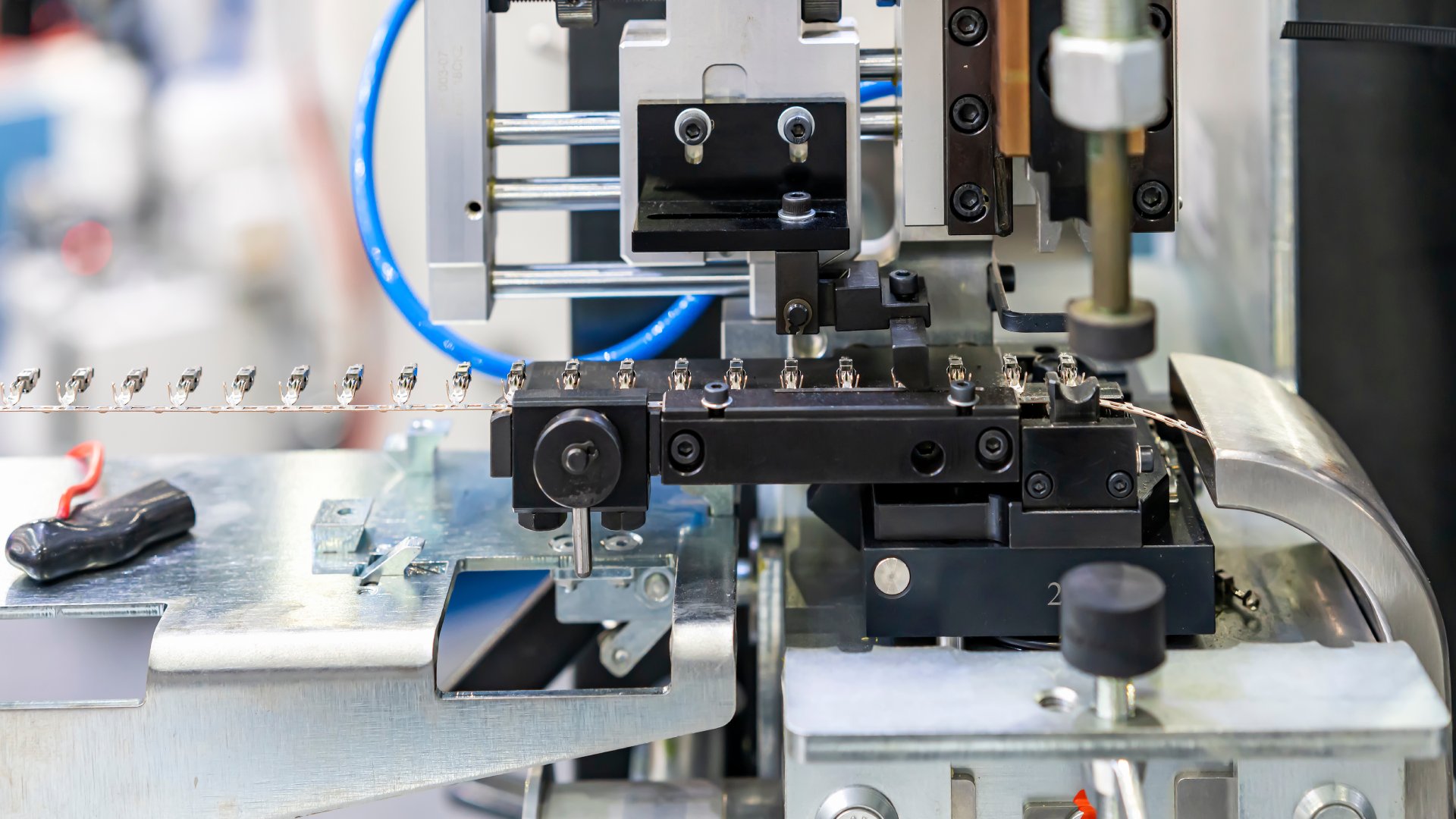

An automatic crimping machine attaches connectors to wires with precision and minimal manual input. Common in industries like automotive, aerospace, electronics, and telecommunications, these machines automate tasks such as wire feeding, stripping, and crimping. They’re essential for creating reliable wire connections and are a significant upgrade from manual or semi-automatic crimping solutions thanks to their integration of advanced automation features.

Advantages of Adding an Automatic Crimping Machine

There are many benefits to investing in an automatic crimping machine for your manufacturing process, from its efficiency to its consistent accuracy. We’ll dive deep into how each of these qualities can help your manufacturing process become more efficient and safer with an automatic crimper.

Efficiency That Speaks for Itself

Automatic crimpers significantly enhance production speed. Automating wire cutting, stripping, and crimping processes sharply reduces the time it takes to perform these tasks manually.

Manufacturers can handle high-volume orders with ease, scaling their production capabilities without increasing labor costs or sacrificing turnaround times. This efficiency doesn't just impact output—it's a direct contributor to a healthier bottom line.

Accuracy That Delivers Consistency

Accuracy is critical in industrial manufacturing, especially when dealing with wiring and electrical components. Manual crimping can lead to inconsistencies, increasing the risk of errors or poorly connected wires, which compromise the functionality of a final product.

Automatic crimping machines, on the other hand, deliver precise, uniform crimps every time. This level of accuracy reduces the margin for error, enhances overall product reliability, and upholds strict quality standards that many industries demand.

Safety Comes Standard

Worker safety is always a priority in manufacturing environments, and automation plays a key role in minimizing risks. With an automatic crimping machine, operators spend less time engaging in repetitive manual tasks and more time overseeing the production process.

By reducing their physical interaction with machinery, the chances of accidents or fatigue-induced errors significantly drop. Furthermore, most modern crimping machines come with advanced safety features, ensuring that both the equipment and the operator remain safe during use.

Caring for Your Automatic Crimping Machine

To ensure their investment in an automatic crimper pays off, operators must learn how to properly take care of them. Automatic crimping machines, like any high-performance equipment, need regular maintenance to stay reliable, consistent, and efficient.

Operators must learn how to inspect their automatic crimping machine to spot minor issues and faults before they become major problems. Cleaning components such as wire feeders and crimping dies prevent debris buildup, while lubricating moving parts and updating software (if applicable) ensure optimal performance.

Invest in Smarter Manufacturing

Adding an automatic crimper to your manufacturing process is a smart investment that boosts efficiency, ensures precision, and enhances safety. These machines help meet large-scale production goals while maintaining high-quality standards. For industrial engineers, adopting automation isn’t just about keeping up—it’s about staying ahead.