A Quick Guide About Cable and Harnessing Assembly

When it comes to electronics, vehicles, and industrial equipment, cables and wiring keep everything connected and running smoothly. Behind the scenes, cable and harness assemblies play a huge role in organizing and protecting the wiring that powers essential systems. Whether you're building a machine, a vehicle, or a custom electrical device, understanding cable and harnessing assembly helps you make smart choices for efficiency, safety, and performance.

What Is Cable and Harnessing Assembly?

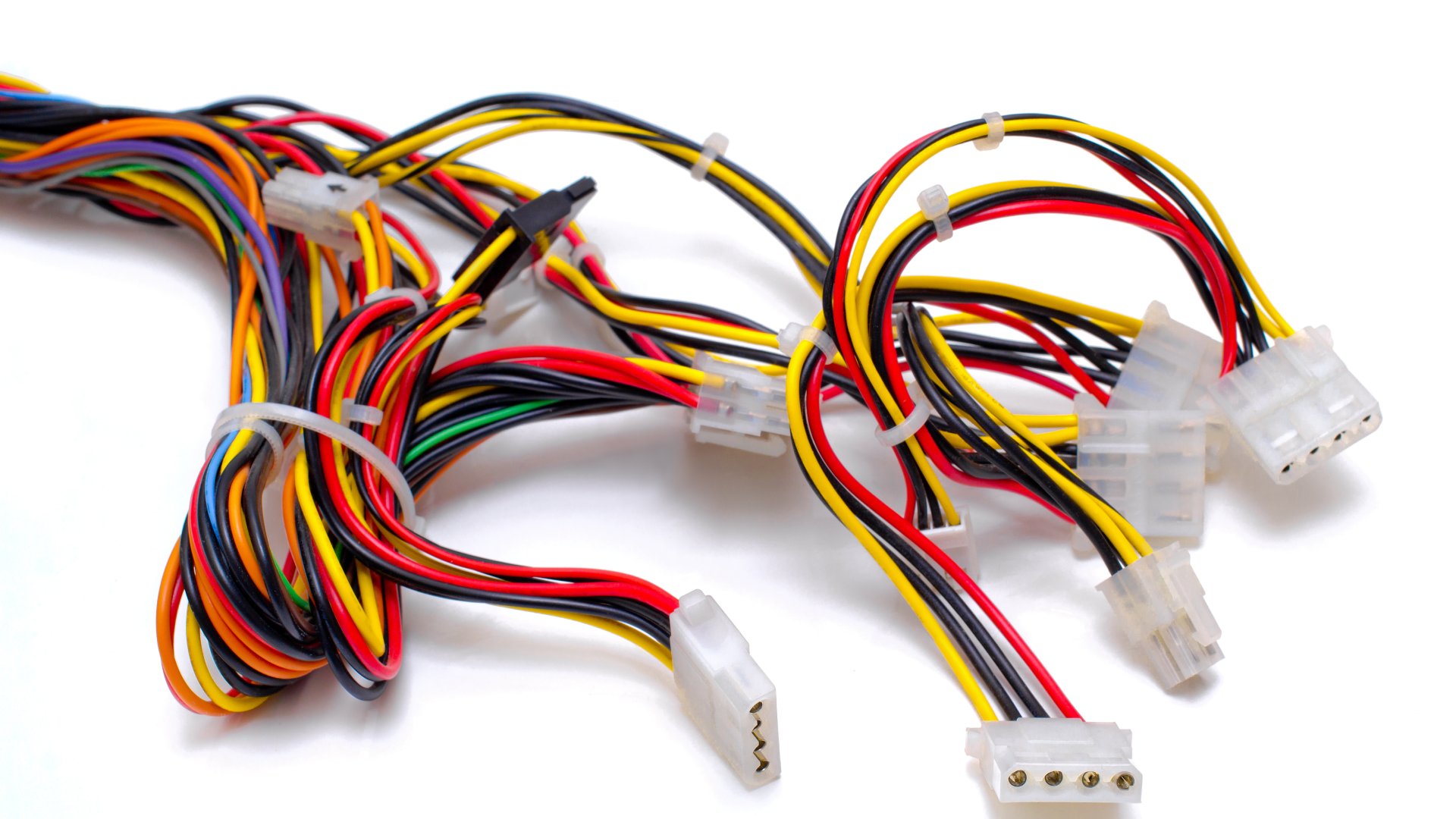

Cable and harnessing assembly involves grouping multiple wires or cables into a single, organized unit. These assemblies help protect the wiring from damage, reduce clutter, and facilitate easier installation. In many systems, wires run through tight spaces or experience regular movement, so grouping them inside a harness keeps them secure and improves durability.

Each harness assembly includes connectors, terminals, protective sheathing, and labels. Manufacturers design these assemblies to fit the specific layout and requirements of the equipment they go into. The right layout prevents interference, reduces installation time, and supports maintenance by keeping wires identified and accessible.

Why Cable Harnesses Matter

Cable harnesses serve a functional purpose beyond keeping wires neat. They improve safety by preventing shorts and electrical faults. In vehicles and machines that vibrate or move a lot, loose wires can wear down or snap. Harnesses hold wires in place and add an extra layer of protection against physical stress, moisture, and heat.

In environments with strict regulations, such as the aerospace, automotive, and medical industries, cable harnessing helps meet performance and safety standards. Even small wiring issues can lead to big problems in these fields, so building solid, reliable harnesses makes a big difference.

Steps in the Assembly Process

Creating a cable harness starts with design. Engineers map out the wiring layout based on the equipment's needs and space constraints. Then, they cut the wires to the correct lengths, attach terminals or connectors, and group the wires using tape, sleeves, or other protective coverings.

Each step requires precision. Technicians must route wires correctly, crimp connectors securely, and inspect every assembly for quality. Mistakes at this stage can lead to electrical failures later, so attention to detail is crucial throughout the process.

Consider Outsourcing Cable Harness Assembly

Outsourcing cable harness assembly makes sense for companies seeking to save time, enhance quality, or scale production. Not every business has the tools or staff to build harnesses in-house, especially when the designs grow more complex or need higher volumes. Working with a partner who specializes in harness assembly allows you to focus on your core business while still receiving high-quality, consistent wiring solutions.

Outsourcing also opens the door to experienced technicians who understand industry standards, use professional-grade tools, and can adapt quickly to design changes. For startups or companies expanding their product lines, outsourcing supports faster growth without the stress of building everything internally.

Cable and harnessing assembly plays a key role in reliable system performance. Whether you're building a one-off prototype or producing equipment at scale, taking the time to understand the process helps you make better decisions. A well-designed harness saves time, reduces risk, and supports long-term success for any electrical system.