Newcastle oil refinery restarts operations after it ‘went boom’ in February

FROM WYOFILE:

No injuries were reported in the incident, which took 20K barrels per day out of production. Refinery officials decline to offer details about the cause.

The Wyoming Refinery in Newcastle has resumed operations months after an apparent explosion in February forced the facility to remain idle for repairs.

The refinery shut down following the Feb. 12 incident, which refinery owner Par Pacific of Houston called an “operational upset.” The company would not provide details of what happened beyond “the main crude heater needed to be replaced” and that there was an “unexpected and unavoidable equipment malfunction,” according to WyoFile interviews and company communications with state officials.

Weston County Emergency Management posted on Facebook the night of the incident that “a heater blew up” at the refinery.

No injuries were reported.

While some fuel production resumed on April 21, it will be some time before the refinery is back to full capacity of 20,000 barrels a day, Dallas Scholes, Par Pacific’s government and public affairs director, told WyoFile.

“When you bring one of these facilities back online, you’ve got to take it slow,” Scholes said. Because the equipment has been idle for months, making sure everything is running correctly and safely takes time, from bringing the heat up to making sure the oil can move through. “There’s a lot that is involved, and our No. 1 priority in this whole process is to make sure it’s safe, and that’s what we’re focused on.”

The company is not projecting when the refinery will resume full operational capacity, but it is providing updates on a website dedicated to the incident.

Even with fuel production shut down, the refinery’s workforce has been hard at work, according to Scholes.

“They are some really incredibly hard-working people, and they were doing a lot of extra shifts,” he said. “We used everybody we could on site, and we brought in a lot of really good experts to fill in the gaps and to make things work. They were gainfully employed the whole time. I’m really proud of what they were able to step up and do.”

The facility produces gasoline, diesel, jet fuel and propane from Powder River Basin crude, according to the company. The economic impact on the region motivated Par Pacific to get the refinery back in operation as soon as possible, Scholes said.

“We stored a lot [of unrefined crude], but that is one of the reasons why we wanted to work as fast as we could — so that we can make sure that oil is still flowing and still available, and to make sure that our producers are still gainfully employed at the end of the day as well.”

The ‘explosion’

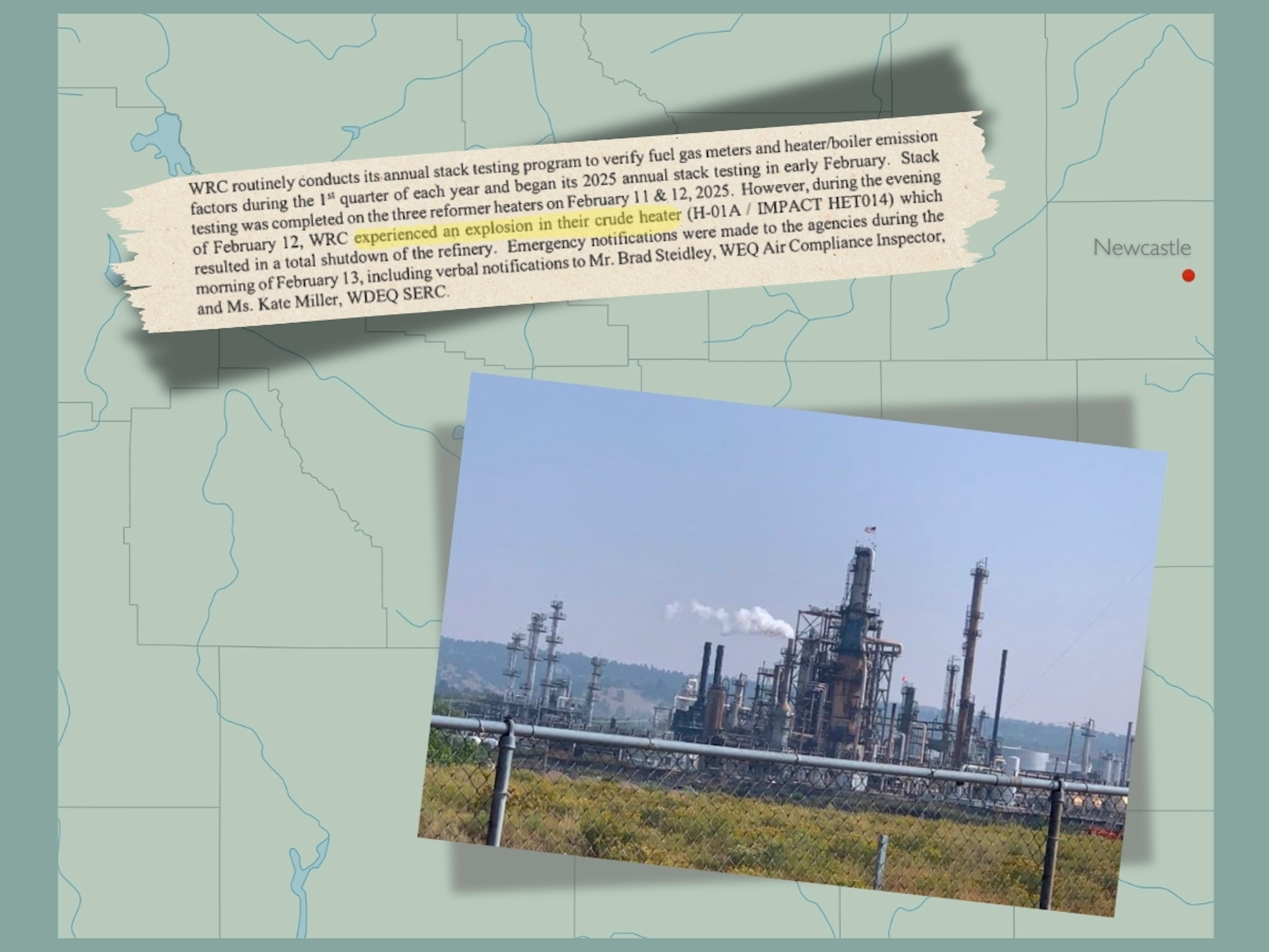

The company doesn’t use the term “explosion” in public-facing communications, and instead refers to the incident as an “operational upset.” However, in a March 24 letter to the Wyoming Department of Environmental Quality, Health, Safety, Security & Environment Manager Michael Baldwin wrote, “During the evening of Feb. 12, [the refinery] experienced an explosion in their crude heater … which resulted in a total shutdown of the refinery.”

The incident did not result in any liquid spills or significant airborne gaseous or powder emissions, according to the company. “There were no emissions that left our fence line,” Scholes said.

Regulatory officials are still in the process of investigating the incident in coordination with Par Pacific.

The cause of the incident remains unclear. The company has refused to elaborate. “That [information] has not been passed on to me,” Scholes told WyoFile.

In a written communication to DEQ, the company refers to an “unexpected and unavoidable equipment malfunction” that occurred at about 10:37 p.m. on Feb. 12.

Weston County Emergency Management Coordinator Gilbert Nelson, who has been briefed by the company multiple times since the incident, told WyoFile, “They were just trying to restart the heater and it went boom.”

Par Pacific is studying what happened to cause the heater failure, Scholes said. “Anytime an incident occurs, we’re all hands on deck to come do an investigation to look for lessons learned that we can apply to any of our other facilities.

“Oil and gas refineries can be a dangerous profession,” Scholes added. “Things can go wrong, and we live every day doing everything we can to make sure that they don’t. And we were just incredibly lucky, and we developed new systems. We do new checks. This is not something anybody wants to see repeated, so you can bet that we will do everything we can to make sure it doesn’t happen again.”

In the days following, the company’s public updates noted a lingering cold snap and notified locals that they would likely see more steam than usual as crews used boilers to try to keep equipment from freezing. “It was 20 below zero when all this was going on,” Scholes told WyoFile.

The company also notified residents there would be more flaring than usual. Refineries frequently burn residual petrol vapors to reduce their hazardous effects, resulting in a flame at the top of a stack. Later, the refinery asked the state for permission, which was granted, to use a temporary boiler to prevent equipment from freezing, state documents show.

History of incidents

The refinery is situated just south of West Main Street and a half-mile from Newcastle High School. The refinery was established in 1927, and officials are quick to point out that it was the town — at the edge of the Black Hills with a population of about 3,300 — that grew around it.

Par Pacific, which also operates refineries in Hawaii, Billings, Montana and Tacoma, Washington, acquired the facility in 2016.

Under a previous owner in the 2000s, Denver-based Hermes Consolidated, Inc., the refinery was known for a series of mishaps, including a March 2002 spill that rained 20 tons of silica catalyst over a portion of the town, resulting in a 2008 settlement with 47 Newcastle-area residents. Details of the settlement were not disclosed. In the latter part of that decade, the refinery received nine “notices of violation” from Wyoming DEQ, resulting in $427,400 in civil penalties.

The U.S. Environmental Protection Agency also took action against the refinery at the time.

The company paid a civil penalty of $150,000 in 2009 and agreed to invest $14 million in upgrades to settle several alleged emission violations cited by the EPA. In 2010, Wyoming Refining paid a $157,500 penalty to the EPA for “failure to prepare, submit, and implement an adequate and complete Facility Response Plan.”

Scholes said Par Pacific prioritizes safety and environmental compliance. “We have certain standards at Par that may not have been there before, and we are constantly working to improve operations.”

A 2023 Wyoming DEQ inspection report, the most recent available, determined, “There were no noted concerns during these inspections.” The inspection report also listed the refinery as being in “substantial compliance.”

“The safety of our workers and the community is our No. 1 priority,” Scholes said. “We’re very proud of our employees that live in the Newcastle community, and they stepped up. They did great work in bringing this facility back to where it can eventually get fully online.”

From 2017 to 2022, Wyoming’s overall oil refining capacity shrank by 27% — from 177,500 barrels per day to 125,850, according to the U.S. Energy Information Administration. The state went from five oil refineries to four in 2021 when HollyFrontier Sinclair converted its Cheyenne oil refinery to produce “renewable diesel,” which uses agricultural products — not oil — to produce the fuel.

WyoFile is an independent nonprofit news organization focused on Wyoming people, places and policy.

This story was posted on May 2, 2025.