How To Make Your Laser-Cutting Process More Efficient

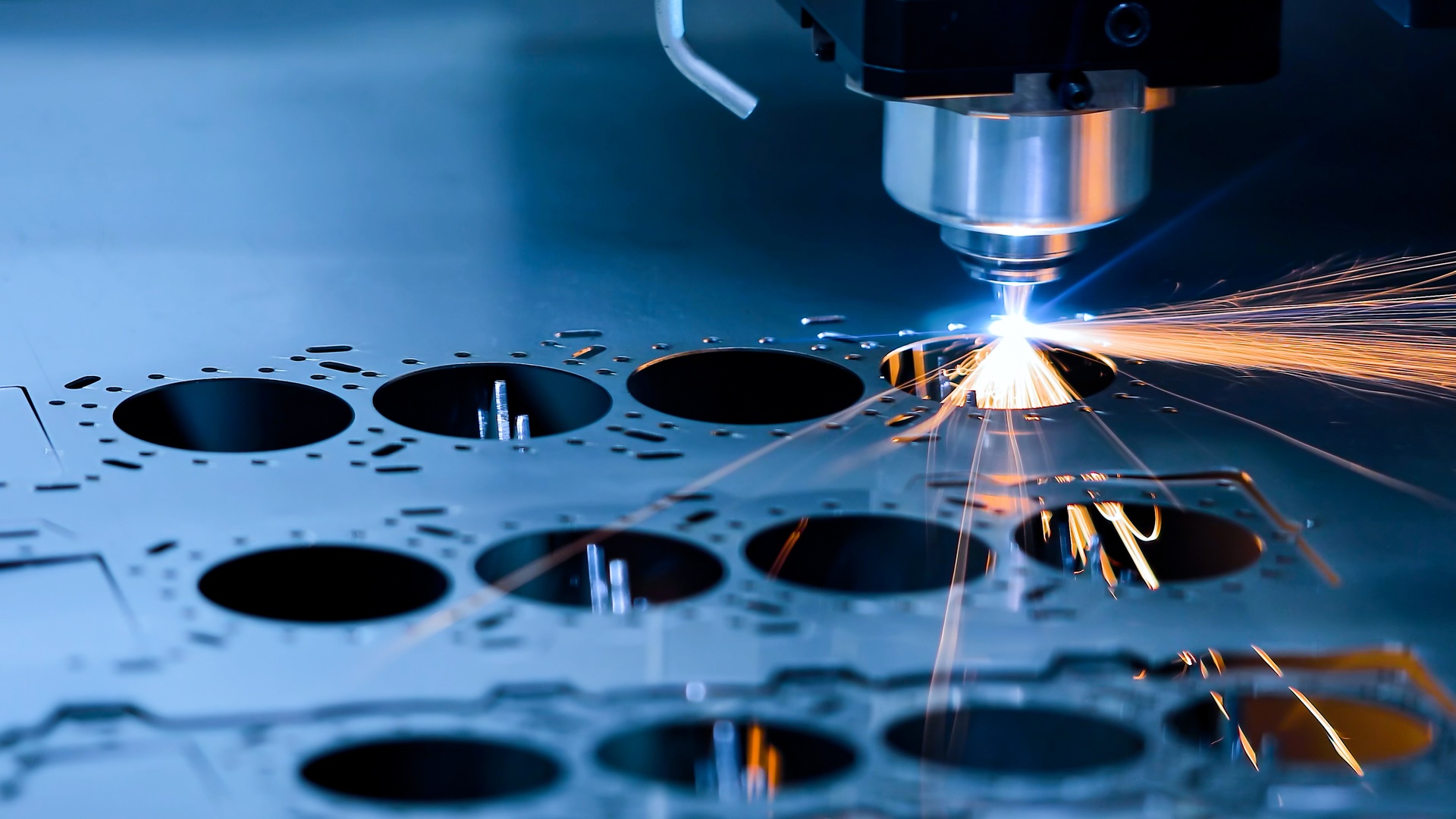

Laser cutting is a powerful tool for creating precise, detailed work across a wide range of materials—but like any process, there’s always room for improvement. Whether you're running a small shop or managing a larger production line, streamlining your laser-cutting workflow can save time, reduce waste, and improve overall quality. In this post, we’ll explore practical tips and techniques to help you make your laser-cutting process more efficient and effective.

If you’re ready to get cleaner cuts and smoother workflows, here are five smart ways to get started.

1. Review Your Workflow

Delays often come from small process hiccups. If you find yourself waiting on design files, prepping materials at the last minute, or digging through emails for job specs, it’s time to streamline. Creating a simple checklist with everything from the initial order to the final cut can help you spot (and fix) slowdowns.

Also, make sure your cutting method fits the job. There are six different types of laser cutting to know, including CO₂ and fiber options. Choosing the right tool for the material can improve both speed and accuracy.

2. Standardize Prep and Materials

Standardizing the preparation process is another major driver of improvement. Using consistent file types, naming conventions, and materials reduces miscommunication and setup delays.

Additionally, nesting designs more strategically on sheets minimizes scrap and optimizes cuts. If your team handles custom work, providing them with templates or layout guidelines can decrease rework and eliminate guesswork.

3. Keep Equipment Maintained and Calibrated

Of course, even a flawless workflow struggles if the equipment isn’t running at its best. Routine maintenance, calibration checks, and software updates help your machines operate more efficiently and accurately.

Staying on top of consumables, such as lenses and assist gas, also helps avoid unexpected slowdowns. Refer to the manufacturer's recommendations or industry standards to determine the lifespan of your equipment.

If your equipment is aging, small component upgrades or firmware enhancements may boost output without requiring a total replacement.

4. Invest in Training and Flexibility

Beyond hardware, the human element matters just as much. Teams that are cross-trained and well-versed in your production standards can step in as needed, ensuring smooth operations during peak periods or in the event of unexpected absences. Standard operating procedures, when clearly documented and shared, help everyone stay aligned, especially in fast-paced production environments.

5. Outsource Select Jobs Strategically

Finally, it’s worth remembering that not every job has to be completed in-house. Overflow work or specialty cuts can often be outsourced to maintain delivery timelines without overextending your team.

This approach is particularly useful if you’re exploring various business ideas and seeking ways to scale efficiently without incurring additional overhead.

Take Your Efficiency to the Next Level

Making small improvements across your laser-cutting operation can lead to significant gains. Better systems, smarter training, and thoughtful outsourcing can all work together to strengthen your bottom line while maintaining high quality. These insights provide a strong foundation for knowing how to make your laser-cutting process more efficient.