The Benefits of Nylon for Plastic Machining

Nylon is the material of choice for plastic machining thanks to its unique qualities, such as its unmatched performance and versatility. It’s widely trusted by engineers and manufacturers. Below, we highlight the many benefits of nylon for plastic machining.

Durability That Beats the Competition

A top reason that nylon is one of the best plastics for machining is its exceptional durability. It resists wear and tear, making it ideal for parts under constant stress or heavy use. Unlike other plastics, nylon absorbs impacts without cracking or breaking. This toughness provides long-term reliability and saves manufacturers time and money.

Lightweight With Heavyweight Benefits

Despite its durability, nylon is surprisingly lightweight. It balances strength and weight, making it perfect for moving parts where reducing weight is crucial. This feature increases efficiency in machinery and reduces power consumption without sacrificing reliability.

Handles Friction Like a Pro

Manufacturers value nylon for its excellent resistance to friction. Machined nylon components work smoothly against other surfaces like metals without damage. Nylon’s low-friction property reduces wear on the material itself and the parts it interacts with, keeping systems running smoothly for extended periods.

Temperature-Resistant and Reliable

Nylon is a high-performance material capable of withstanding diverse temperatures. It resists deformation under increased heat, promoting stability in demanding environments.

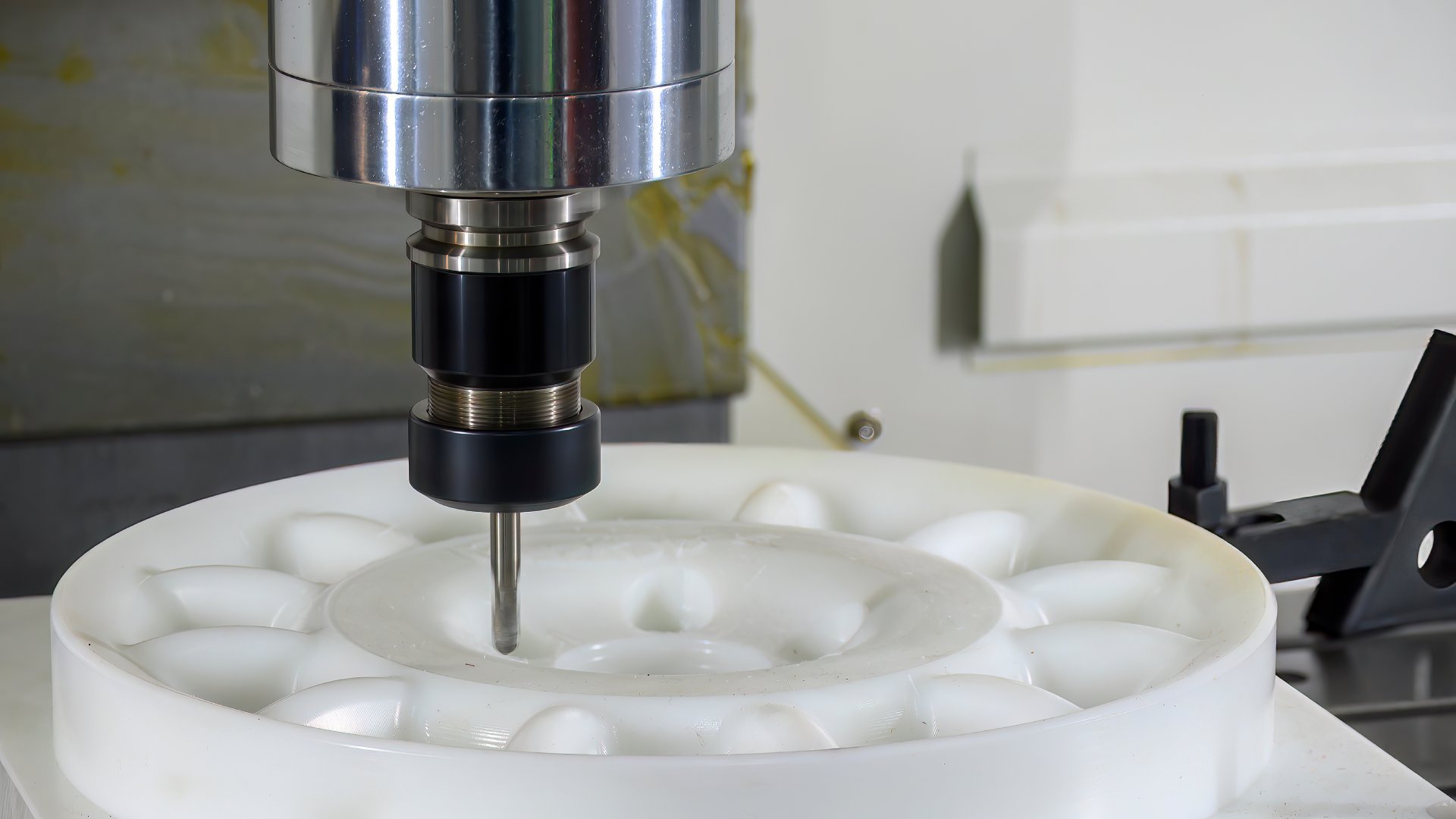

Easy To Machine

Machinists love working with nylon for its ease of handling cutting tools. Unlike harder plastics, nylon doesn’t damage equipment yet still produces precise parts. Its machinability results in clean finishes and reduced waste, saving production time while maintaining tight tolerances effortlessly.

A Cost-Effective Choice for Manufacturing

Another benefit of nylon for plastic machining is its high value at a reasonable cost. Compared to metals or other engineering thermoplastics, nylon is affordable without cutting corners on quality. Its durability and reliability make it an economical option for manufacturers looking to maintain budgets while achieving premium performance.

Chemical Resistance for Longevity

Nylon resists oils, solvents, and chemicals. This advantage makes it a favorite in industries like automotive and manufacturing. Components stay strong and stable, even in environments exposed to corrosive materials.

Nylon brings various advantages to plastic machining that make its use practical and essential for many applications. Its properties combine to create a material that balances toughness, flexibility, and cost-efficiency. Whether in machinery, automotive, or industrial parts, nylon consistently delivers reliability where it matters most.